Installation And Usage Of Magnetic Valve

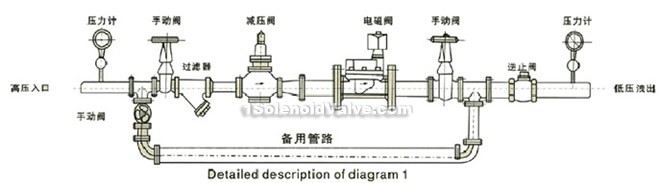

installation scheme

Installation and usage of magnetic valve constructral diagram

1, before installation should refer to the use of the product specification, meets your demand.

2 pipe, rinse clean, before the use of the media should not be clean install filters, in order to prevent the impurity hinder the normal work of the electromagnetic valve.

3, electromagnetic valve is generally one of the work. Cannot reverse, valve arrow is the movement direction of flow in the pipeline, must be consistent

4, solenoid valve, the general level of installation of coil vertical, some products can be installed arbitrarily, but in the best condition allows, with growth coil vertical life-span.

5, solenoid valves in icy places to work with, or Settings should heat preservation measures.

6 and electromagnetic valve lead wire coil (connectors) connected, should confirm whether firmly, electrical components contacts should not shake, loose will cause electromagnetic valve does not work.

7 and continuous production work, had better use of electromagnetic valve by-passes shall not affect the, easy maintenance.

8, after discontinuation of for a long time, should be clear electromagnetic valve, which can be used only, Each parts according to unpick to restore order.

9 and unknown place the company each big sales general with accessories, can for your inquiry services.

First .Failure of magnetic valve

A solenoid valve, after electrify doesn't work

1.Check whether the power cables, poor - - - - - the rewiring of connections not connectors

2 and check whether the power supply voltage range within ±range - - - - - to normal position

3 coil is welded off - - - welding

4 and winding - - - - - replaced coil

5 and differential pressure is not appropriate - - - - - - - adjustment differential pressure - - - - - or replacement of solenoid valves

6 high humidity, fluid - - - - - the replacement of solenoid valves

7 and impurity to electromagnetic valve of the main valve core and moving iron core jammed - - - - - such as cleaning, there should replace the seal and seals damage to install filters

8 and liquid viscosity and high frequency is too big and life has to - - - - - replaced product

Second, the electromagnetic valve cannot be shut down

1, the main valve core or iron core of seal fixed damaged - - - - - replace the seal

2, whether fluid viscosity and humidity high, - - - - - the replacement of the electromagnetic valve

3 and impurity into solenoid valve core vice or moving iron core - - - - - cleaning

4 spring life has to or distortion - - - - - the replacement

5 and orifice balance aperture blocked - - - - - timely cleaning

6 and high frequency or life is over - - - - - the product or replace product. Re-selection

Third, other conditions

1, internal leakage - - - - - check seals, spring is whether the damage to the assembly

2 and external leakage - - - - - joint loose or seals have been bad - - - - - - - the screw or replace the seal

3 – noise power on, - - - - the loose, tighten fasteners judenrein-jew-free. Voltage fluctuation is not allowed, adjust voltage. Core and surface impurity or uneven, timely clean or replace.